CASE STUDY: Robots in architecture and custom construction

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

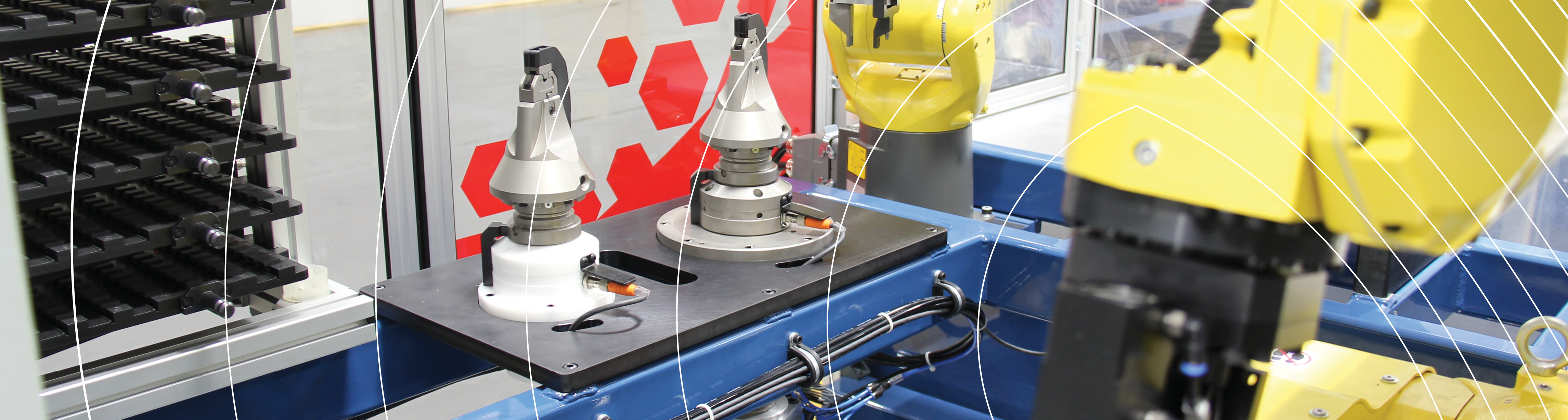

UAP is a Brisbane headquartered company that manufactures public art, custom architectural facades, and design furniture for leading artists, architects and designers around the world. The complexity of designs that artists, architects and designers now demand push the limits of what is feasible to manufacture with traditional fabrication techniques.

To meet this demand and ensure future competitiveness, UAP has invested in a 5-year Design Robotics project with the Innovative Manufacturing Cooperative Research Centre (IMCRC). This project is to investigate how robotic vision could be applied to its manufacturing processes, to make them more cost effective and allow for new kinds of art and design objects to be created.

The first problem that robotic vision is addressing for UAP is to allow for robotic polishing of metal sculptures after they are removed from a sand mould. This is a labour-intensive, dangerous and boring job that is currently difficult to automate because of the unpredictable shapes involved. Unlike in mass-manufacturing, where the actions of the robot can be programmed ahead of time, in UAP’s manufacturing processes the items are often completely unique with no pre-existing computer file that describes their shape. Robotic vision is required to build an accurate model of the cast metal object that can be used to drive the polishing process.

Already UAP are reshoring work back to Australia from China due to the cost benefits associated with scanning and robotic technology. 50 hours of robotic operation allowed 800 labour hours to be re-shored back to Australia.

Trending Article

An Australian university (ANU) has been the first to trial intelligent drones for automated inspection of solar power plants.

The project is an industry-researcher collaboration funded by the Australian government’s Australian Renewable Energy Agency (ARENA) developing a cost-effective robotic inspection system…

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

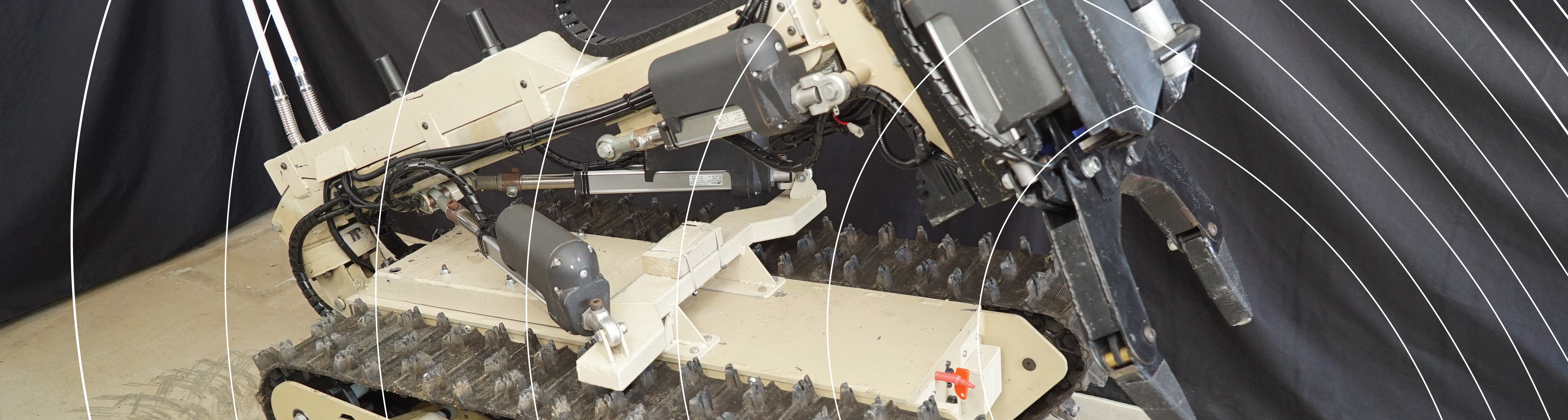

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.