Robotics and the resources sector today

Australia’s mining innovation efforts to date have resulted in the country being recognised as a low-cost producer in iron ore, and Rio Tinto becoming the world leader in mining automation. The economics of autonomous haulage systems (AHS) show gains achieved via: reduction in fuel consumption (~10%), maintenance costs (14%), tyre wear (12%), labour cost (5-10%), and truck life time (12%). Autonomous fleets outperform manned fleets by an average of 12 per cent, primarily by eliminating required breaks, absenteeism, and shift changes. Over the past eight years, Rio Tinto has spent about $AU1.5 billion on technology programs in iron ore, including its automation efforts and an Operations Centre in Perth. This is no small sum when placed in the context of the federal government’s recent announcement to spend around $AU1.1 billion over four years on economy-wide innovation efforts. Rio Tinto’s actions and expenditure demonstrate the central role that the private sector must play in developing and adopting new ideas and converting them into real productivity improvements [BAE16].

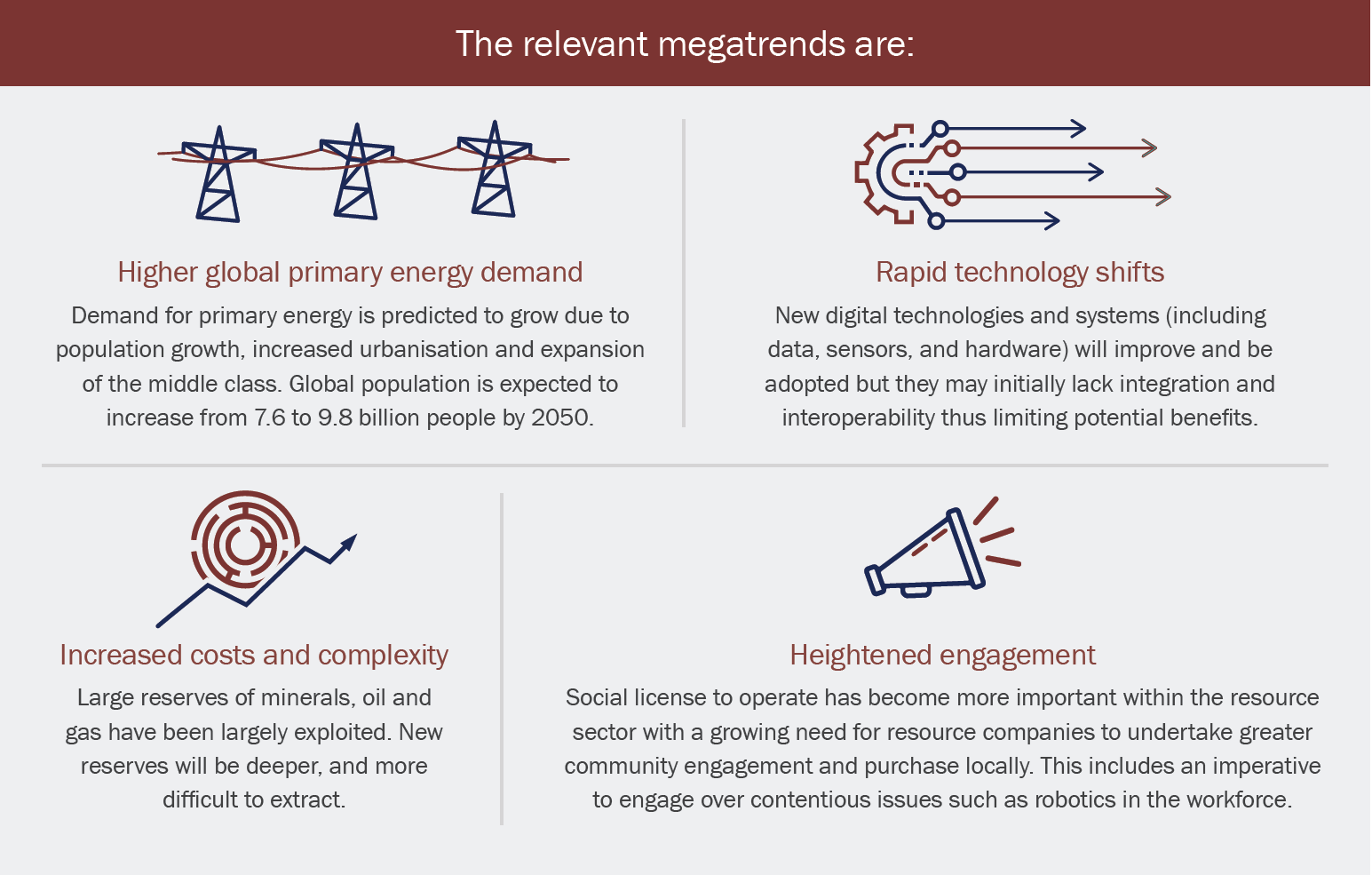

The nature and scale of activities in the resources sector sets it apart from other sectors. While the average life expectancy for Fortune 500 companies is only 15 years [BBC12], just the production phase from a mine site can continue for 40 years or more [AM17]. The resources sector also draws upon significant financial, human and natural resources due to the nature and scale of its activities. The impact on the resources sector from global megatrends identified by the CSIRO, will be partially addressed by robotic technologies [CS17].