CASE STUDY: Kalmar – AutoStrad Terminal Solution

Case Studies

Since 2014, XM2 Aerial has been pioneering the use of unmanned aerial …

Go.Robot is an Australian company that distributes and configures robotic …

Laing O’Rourke – lifting frontline job satisfaction

Laing O’Rourke is a $AU6 billion international operation with 50 years of involvement …

Co-designing a robot for Indigenous Australian language revival

Opie the Robot is a technology deployed in classrooms in the southeast …

In the back streets of Brisbane, two brothers with a passion for the automative …

Share this story

Within the next 10-15 years many of the major stevedores will automate and the AutoStrad will be an attractive proposition for many of these operators” says Matt Hollamby, Brisbane Manager, Terminals Division, Patrick Corporation.

Kalmar’s automated straddle carrier terminal is a proven, modular, scalable and flexible automation platform that uses state-of-the-art vehicle navigation systems, combined with the advanced terminal logistic system (TLS) for equipment control.

At the heart of the solution is the automated straddle carrier (AutoStrad): a driverless straddle carrier that can automatically pick, transport, and place containers, providing free-ranging horizontal transport at speeds of up to 30 kilometres an hour. The straddle supports ISO 20, 40 and 45-foot dry containers and reefers, provides twin forming and lifting, and interchanges with quayside operations, truck, automated stacking cranes, rail mounted gantries, and manned reach-stackers.

In 2005, the first fully-automated AutoStrad container terminal was opened by Patrick Stevedores in Fisherman Island, Brisbane. This was a collaboration between Patrick Technology and Systems, and Kalmar. In 2012, the Asciano AutoStrad solution was transferred to Kalmar, and the current AutoStrad and AutoShuttle solutions have been developed by teams both in Sydney, Australia and Tampere, Finland. AutoStrad terminals now operate in Patricks’ Botany Terminal, Australia (2015), TraPac LA Terminal, USA (2016) and, VICT Melbourne Terminal, Australia (2017).

Trending Article

An Australian university (ANU) has been the first to trial intelligent drones for automated inspection of solar power plants.

The project is an industry-researcher collaboration funded by the Australian government’s Australian Renewable Energy Agency (ARENA) developing a cost-effective robotic inspection system…

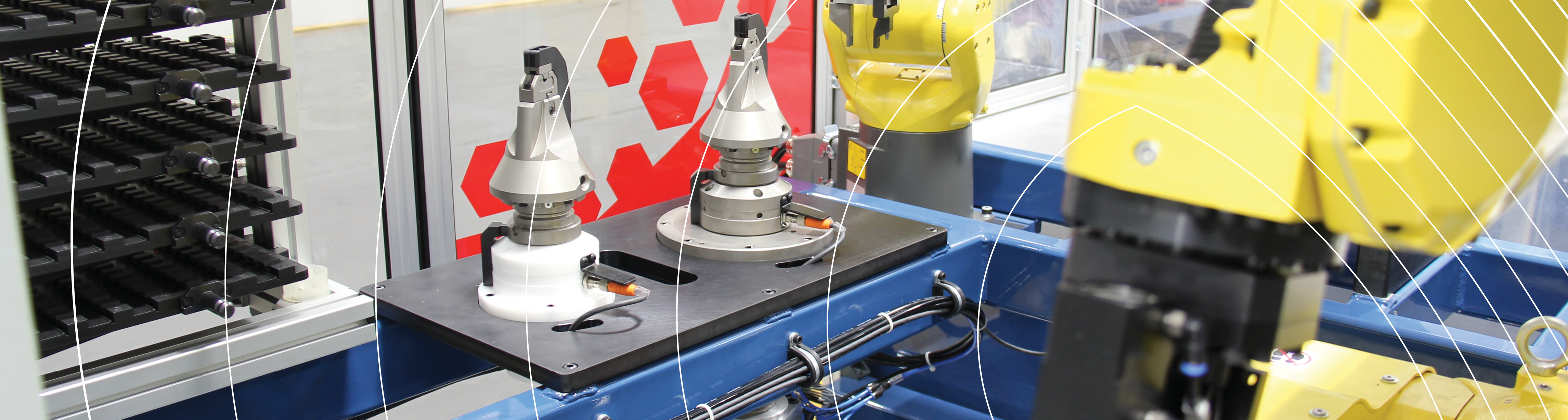

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

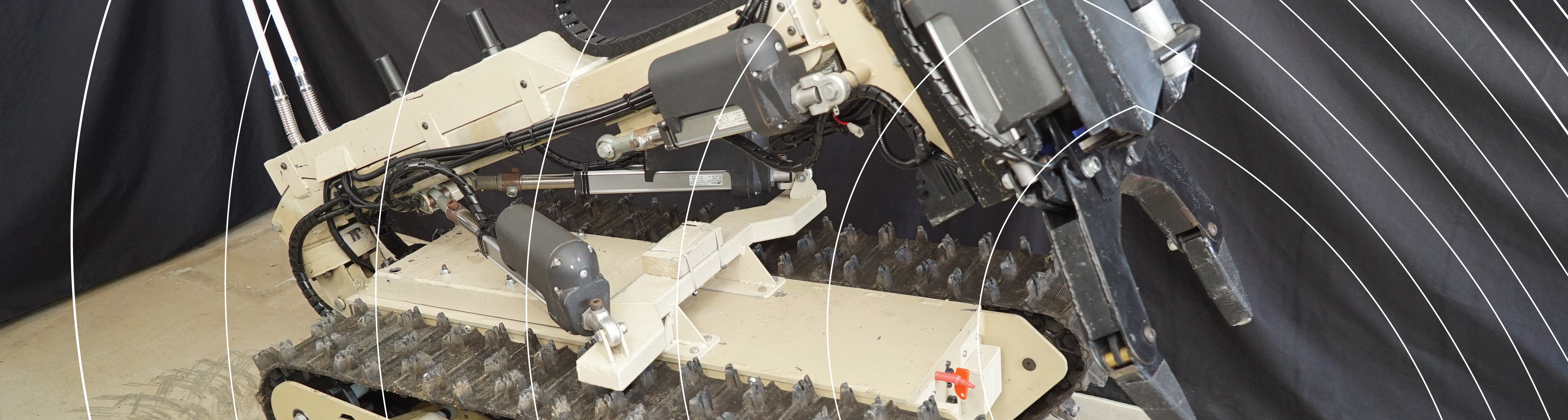

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.