MANUFACTURING

Manufacturing in Australia has been declining since the 1970s, when one in four Australian workers were employed in the sector. However, there are signs of recovery, with strong growth in 2018, particularly in food production.

Australia’s manufacturing sector

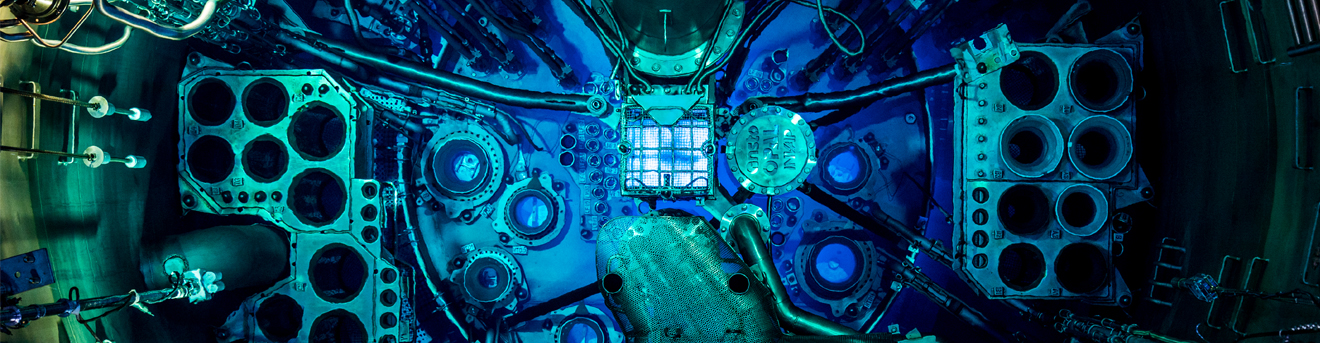

Australia leads the world in niche manufacturing for several high-value industries, including medical technology and aerospace, but needs to adapt to the fourth industrial revolution (Industry 4.0). The “smart factory” of Industry 4.0 has robots connected remotely to computer systems equipped with machine learning algorithms that can learn and then control the robots with little human input [FO18]. Industry 4.0 promises a new era of manufacturing where mass customisation and decentralised production are normal.

Despite its increasingly high-tech nature, modern manufacturing in Australia has an image problem. While the majority of Australians (82.5 per cent) believe the manufacturing sector should be supported, few people want to work in it [SMH17]. The sector is characterised by an ageing workforce and poor gender diversity (men outnumber women by almost 3 to 1) [WGEA16]. The manufacturing industry also has a high number of work-related fatalities, injuries and illnesses, with approximately 18 workers killed each year. Another concerning statistic in the industry is that young workers (those aged between 15–24 years) recorded an injury rate 44 per cent higher than young workers in the Australian workforce as a whole [SWA18].

Manufacturing employs many skilled and unskilled workers. For example, it is estimated that about 40 per cent of engineers are employed in manufacturing and related consulting industries [EA17]. The skills developed by manufacturing industry employees are the core skills that every modern economy depends upon. The manufacturing sector trains many technical and professional people with the skills necessary to install and maintain our telecommunications, energy, water and transport systems. This includes engineers, technicians, welders, fitters and turners. Manufacturing is a net supplier of these skills to other industries, especially the resources sector. Without the skills training that occurs within the manufacturing industry, skill shortages would become more intense [AMWU16].

Manufacturing in Australia has been declining since the 1970s, when one in four Australian workers were employed in the sector. The downturn has gathered pace since the global financial crisis and the loss of Australia’s automotive industry, and now only one in 13 Australians are employed in manufacturing. However, there are signs of recovery, with strong growth in 2018, particularly in food production [CS16].

Currently, about 80 per cent of the value of Australian manufacturing comes from four major sub-sectors: Food, beverage and tobacco products (27%), petroleum, coal, chemical and rubber products (19%), machinery and equipment (18%) and metal products (15%). Overall, the manufacturing sector has gone through a major structural change in the last three decades, where production related to food and beverage, metal and machinery, and equipment has increased significantly. Manufacturing is dominated by SMEs (1-199 employees) responsible for 64 per cent of jobs in the sector. The remaining 36 per cent of employment is created by large enterprises with more than 200 employees [ABS16].

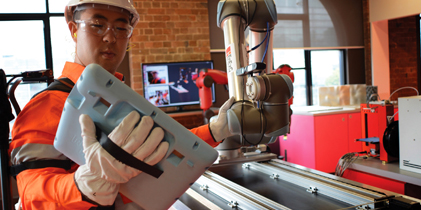

Manufacturing was the first sector to embrace robotics, with prototype industrial robots introduced to the factory floor...

SMEs typically lack the resources to have dedicated automation engineers on staff. Robotics in large manufacturing companies...

If Australia invests wisely and shares people, data, and solutions across sectors, it can grow a national capability to support ...