CASE STUDY: Robotic technologies to look after critical water mains in large cities

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

Failure, and leakage, of pipes in water supply and distribution networks contributes to loss of potable water and has potentially serious economic, political and consequential costs. Water utilities worldwide face this issue, as pipe networks become older and more prone to failure.

The value of Australian buried assets is around $AU80 billion, with significant maintenance and repair costs. In 2011, Australian water utilities embarked on a major initiative focusing on the large cement-lined cast iron critical water mains (CWM) that comprise extended parts of older drinking water networks and are the most vulnerable. Together with US and UK water industry partners and leading-edge research capabilities at various Australian universities, a significant initiative was established, aimed at better targeting pipe renewals as the essential component of a CWM management framework.

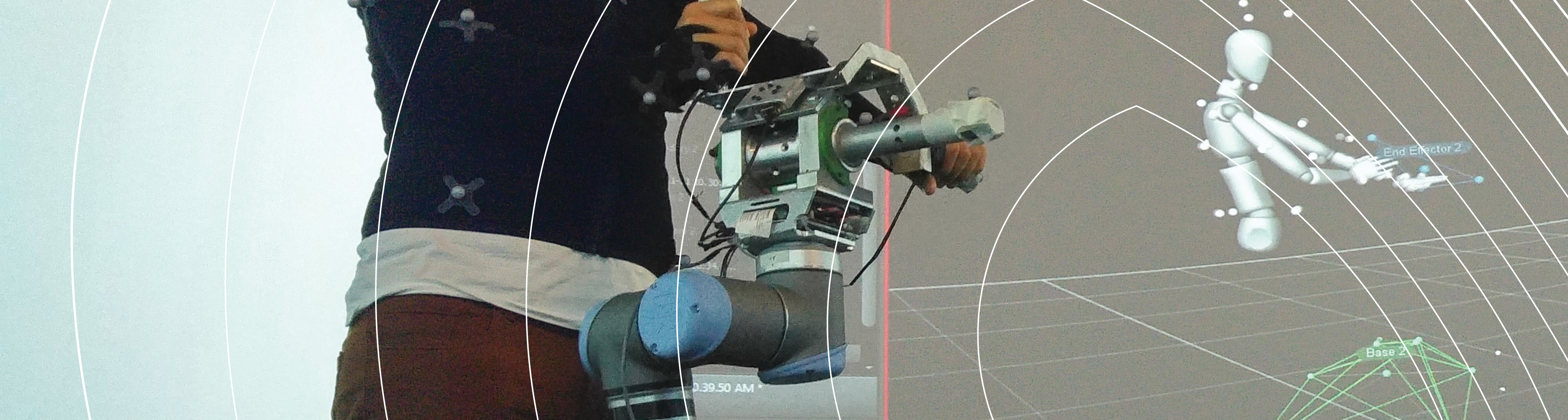

After gaining a comprehensive understanding of non-destructive testing/evaluation (NDT/NDE) condition assessment (CA) techniques and industry practices, the Centre for Autonomous Systems at University of Technology Sydney (UTS) embarked on the development of advanced sensing interpretation techniques with increasing levels of confidence. This work included the design and deployment of bespoke robotic systems for the inspection of CWM. Sydney Water was the major stakeholder in the Advanced Condition Assessment and Pipe Failure Prediction Project (ACAPFP) research scheme with a cash investment of about $AU6 million. In 2016, Sydney Water estimated that learnings from the project had allowed them to advance their current maintenance practices by suitably amending condition assessment contracts and data collection protocols. Sydney Water also recognised a reduction in the cost of the annual CWM renewal program from $AU40 million in 2008-12 to $AU30 million in 2012-16.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

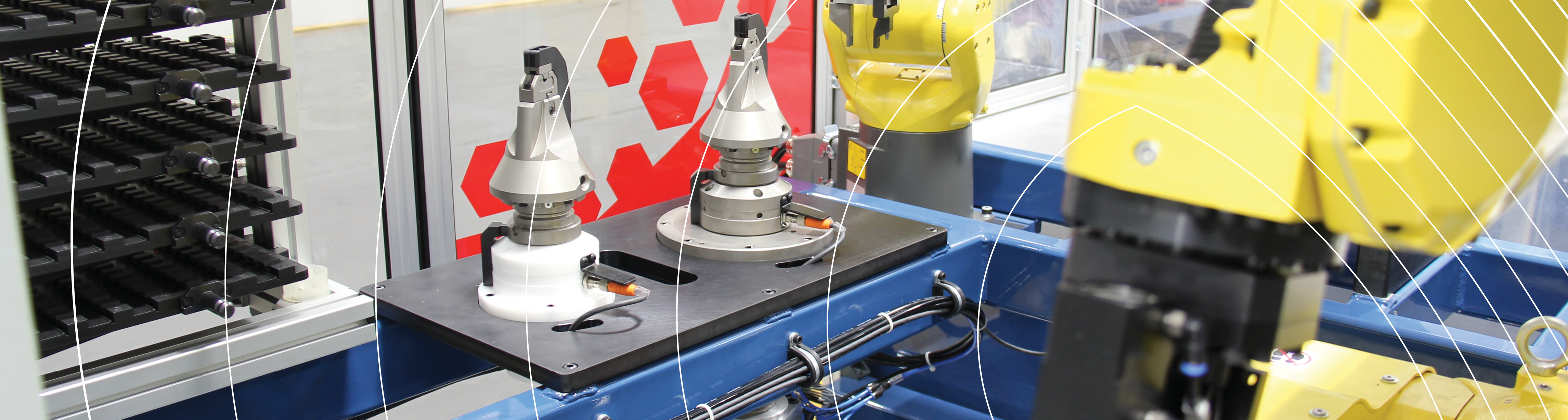

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

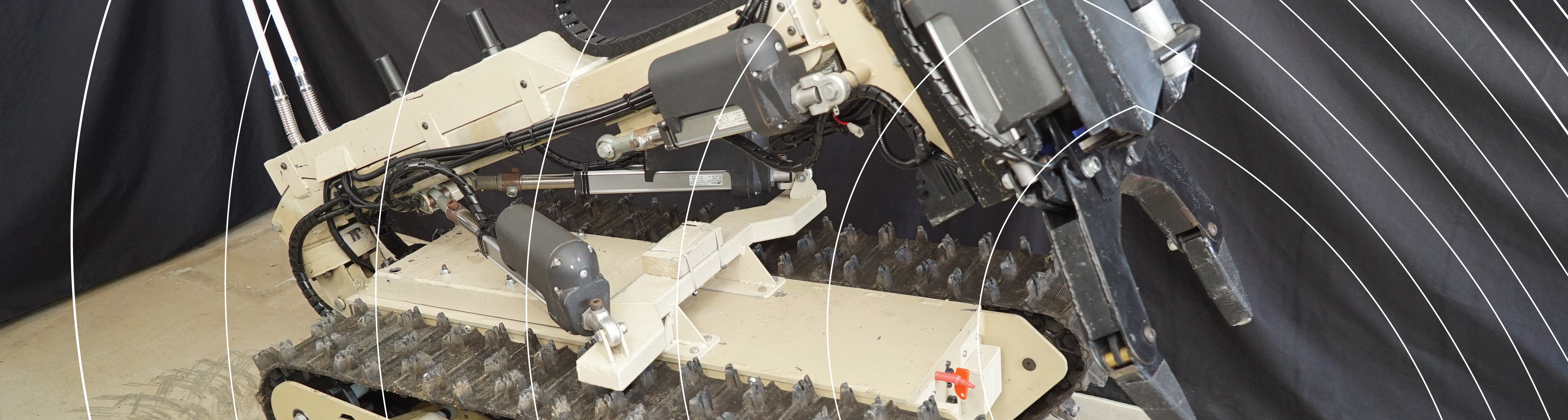

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.