Safety and Standards

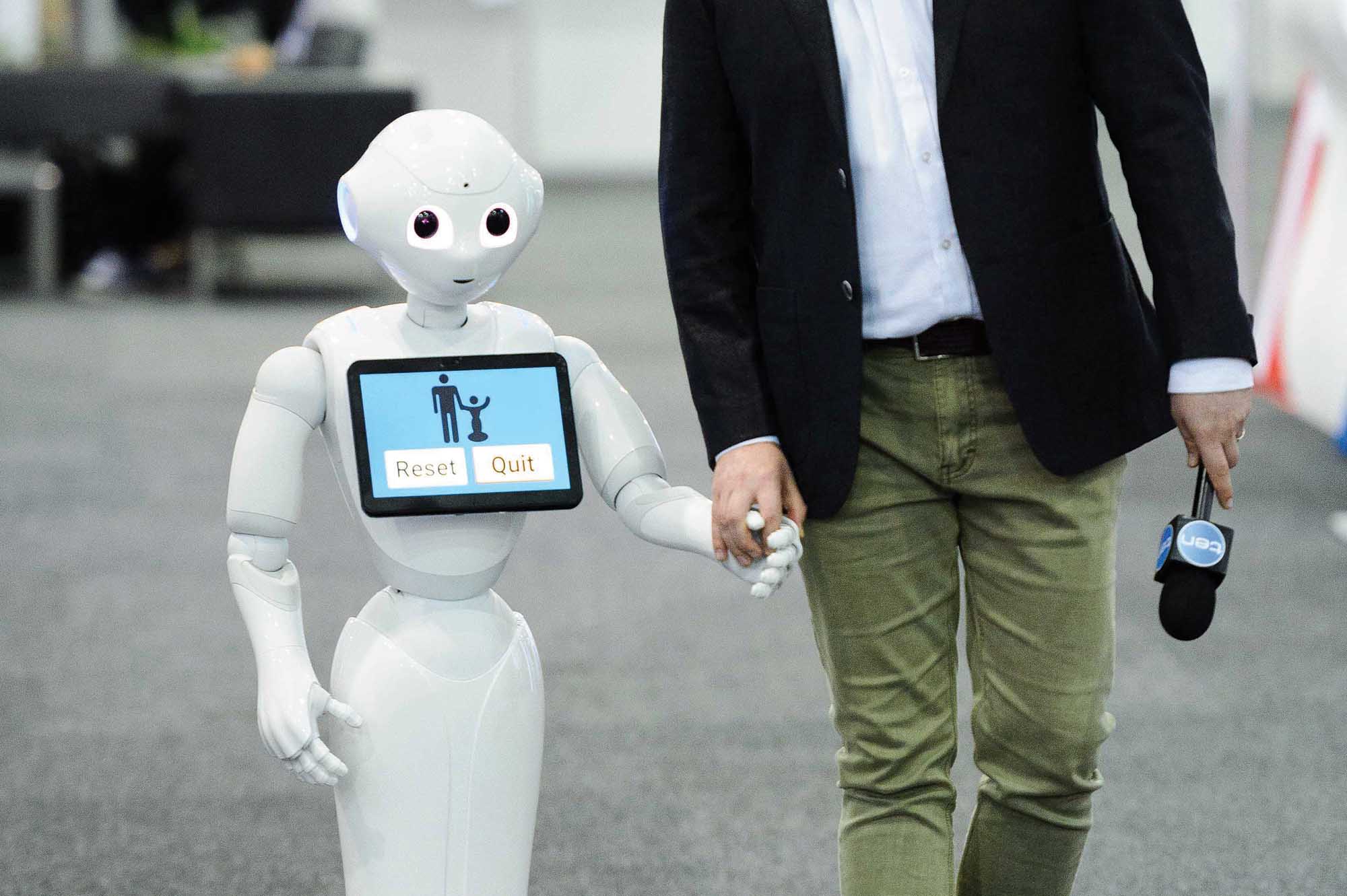

Robots should be safer than humans at achieving the same tasks, such as driving, because they are engineered systems not burdened by human fallibility (except in their conception). Traditionally, robots have operated in interlocked cells, isolated from people to ensure human safety. However, modern robotic systems are increasingly allowing more collaborative applications and it is no longer always practical to keep them physically separate from people. Many robots must operate in public spaces, such as retail robots or robotic vacuum cleaners (see Chapter 7). For this reason, ensuring that robots can operate safely in public, unconstrained environments, where required, is becoming critically important.

Who is responsible for ensuring robots, including imported robots (which account for most of the Australian robot population) are safe? The answer is multi-faceted. The manufacturer (if Australian), the importer, the supplier, the integrator, the designer, the retailer and the employer (where it is a workplace robot) all bear equal responsibility.

Australia has well established standards for industrial robots to minimise risk in industrial settings. The expanding population of service and personal care robots is less well-regulated, however, as these robots are often deployed in a home setting rather than a workplace. For this reason, it is important that Australia has standards for the use of service and personal care robots. There are some international standards for these robots that may be adopted in Australia in the future (for example, ISO 22166-1 Modularity for service robots; ISO 13482:2014 Safety requirements for Personal Care robots). As the demand for robots increases, and new robots become available in the market, there will be a need for new, relevant standards. The development and application of suitable standards is being considered as part of the Australian Government’s work towards a new digital economy strategy [DE17].

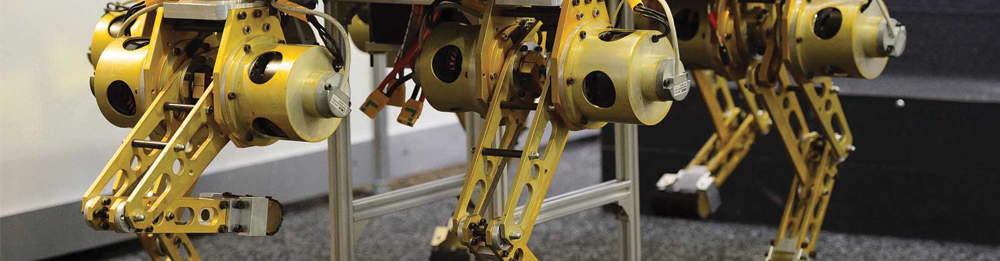

Industrial robots have their own machine specific standards due to their potential strength, speed, and complexity of operation. For example, a person may not be able to predict what a robot will do next as its programming may be complicated, plus the robot utilises multiple sensors which have a probability of dangerous failure. The robot standards define the integrity of safety control systems that are required and the ‘best way’ for ensuring safety of personnel in all modes of operation.

Interoperability is a challenge facing the adoption of automation and robotics, and is a mixture of technological, commercial and regulatory challenges. The Institute of Electrical and Electronics Engineers’ (IEEE) Robotics and Automation Society Standing Committee on Standards Activities is experimenting with standards that allow robots to interact and communicate with other robots, but these standards are not enforceable. Standards for interoperability of autonomous systems should be urgently addressed.

Standards for the safety of vision systems is also an area of concern. Presently, it is not clear when a vision system can be deemed ‘safe’, for example, what level of recognition is required? 100 per cent recognition of people under any weather and lighting conditions? What levels of redundancy are required?