CASE STUDY: Rotacastor – Newcastle company manufacturing robotic wheels

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

Australia Post used ball transfer tables for manual sorting of bulky international mailbags weighing up to 35 kilograms. This required substantial, repetitive manual effort by operators to push, pull and rotate the bags, exposing the operators to potential musculoskeletal injury. To address this issue, Australia Post looked for alternative solutions that would substantially reduce operator input and exposure to risk of injury. With a targeted push/pull force of 50N (5kg) for a 35kg bag, it was acknowledged that this target would most likely require a powered solution, adding to operating and maintenance costs.

The Rotacaster Solution: Rotacaster proposed a manual transfer solution utilising their 48mm Rotacasters combined with polyacetal (POM) spacer rollers. The roller’s smaller diameter was designed to provide support for the soft packaging, while minimising friction and reducing the number of Rotacaster wheels required. Australia Post and Rotacaster collaborated on the design and construction of the transfer table. Trials were successfully undertaken at an Australia Post gateway.

Outcome: The solution resulted in a significant reduction of push/pull forces to between 40 and 70N (4-7kg) in all directions on the table. Australia Post considered this a remarkable achievement in the absence of any powered assistance.

Additional Advantages: In addition to reducing the push/pull forces required, without the cost, noise, and maintenance associated with a powered solution, the polymer surfaces of the Rotacasters and spacer rollers have demonstrated a lower affinity to adhesion of labels and stickers from packages, further reducing downtime and maintenance costs.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

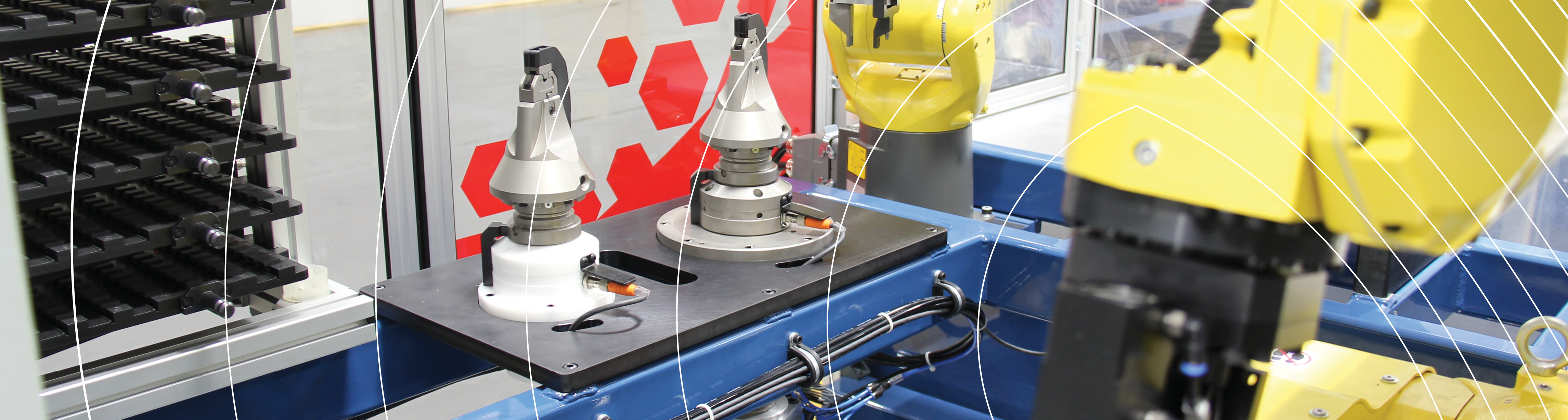

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

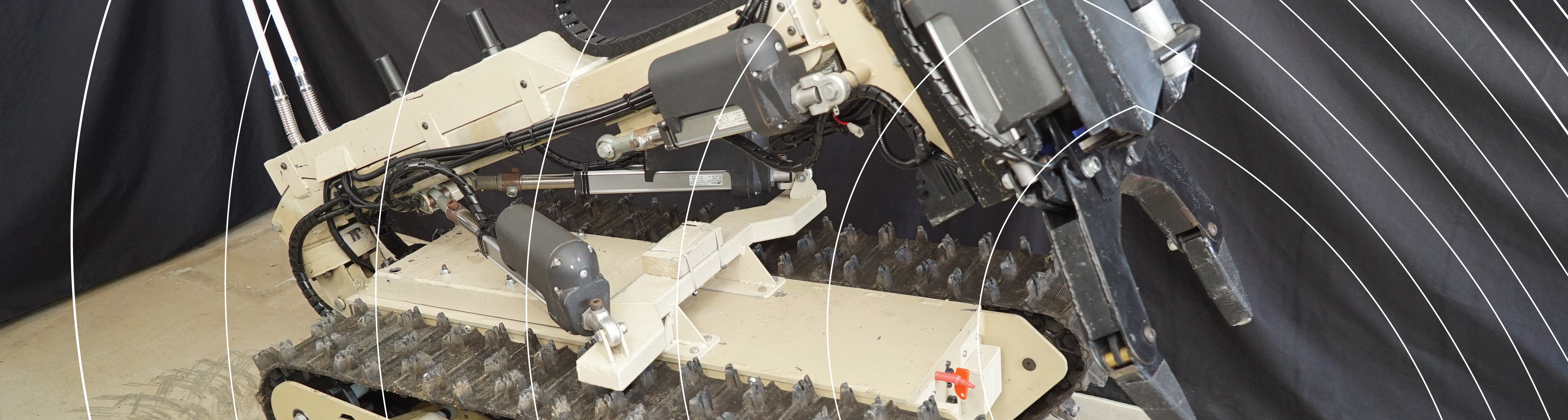

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.