Robotics and the manufacturing sector today

Manufacturing was the first sector to embrace robotics, with prototype industrial robots introduced to the factory floor of automotive manufacturer General Motors in 1961. Since then, robots have become more sophisticated, but until recently, were too expensive for use by SME manufacturing plants and were unsafe to deploy collaboratively with humans in unstructured environments. Technological developments mean that robots are now cheaper, safer, more flexible and can be used in mass customisation or even bespoke applications in ways that were impossible even 10 years ago. However, it is not clear that Australia is benefitting from many of these advances, or that it will be able to harness the benefits of Industry 4.0.

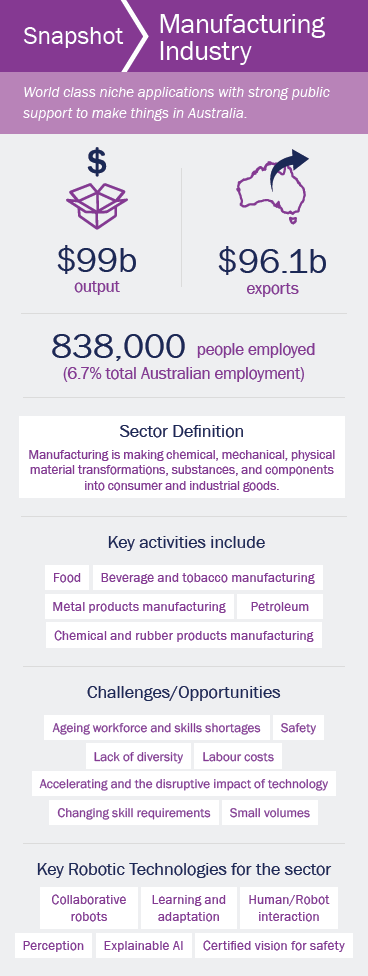

To maintain and grow standards of living, Australia will have to increase productivity. Automation is a key to this and automation in manufacturing, which makes up six per cent of Australian GDP, will be a major contributor to the national well-being, as determined by living standards. In manufacturing, automation will combat relatively high national costs (living and energy costs combined with weak productivity growth) against strong emerging competition in low cost and/or technology- or cash-rich countries and regions.

However, in Australian manufacturing, robotics numbers have flat-lined at around 7,500 installed units, growing only 1% over the 2011-16 period, while the number of robots installed worldwide has grown from 1,147,000 to 1,785,000, a 56% increase. A record 285,100 units were installed in 2016 alone [IFRIR16]. The following data demonstrates why Australia is ranked 18th in the world in robot density in the manufacturing industry [IFRIR17]:

Growth in Australia’s use of industrial robots has been tempered by the demise of the automotive industry (2017), which had a large density of robots per worker. This has magnified the fact that 64 per cent of Australian manufacturing companies are SMEs (between 1-199 employees) with a relatively high ratio of highly-skilled persons to low-skilled labour [PM12]. Australia has a specific need for robotics to act as a force multiplier, augmenting and extending world-class, skilled human capability while reducing human exposure to dirty, dull, and dangerous processes. Full automation of unskilled jobs can be purchased, and Australia needs to develop specific technology to support reskilling and redeployment of the existing workforce.

Automation in manufacturing must evolve to support small manufacturers with a diverse range of needs and capital constraints. Australian manufacturing is not large enough to support the creation of the appropriate tools to deliver these needs alone. However, by investing appropriately and sharing people, data, and solutions across sectors, Australia can grow a national capability to support and expand its niches and compete in the rapidly changing manufacturing world.

Another considerable opportunity is the blurring boundary between manufacturing and other industry sectors, which were once considered discrete. For example, construction is moving towards pre-fabrication while embracing design for manufacture. Assembly principles are being applied to the construction of building elements, in a plant with a mass-customisation mindset, and the assembling of these elements are taking place onsite. This is an opportunity for two discrete and non-competitive sectors who have a shared driving need in the core capabilities robotics offers.